Compatibility

Innovative

Protection

Accuracy

Medical Diagnostic Device Components

Nowadays, there are many different medical diagnostic devices that enable users to monitor and collate information regarding their health. Equipment that measures heart rate or tests glucose levels in your blood are just some examples. These medical innovations utilise technology that produces real-time and accurate data regarding medical conditions that is not only significant for the user, but also vital to their GP too.

With experience of working with medical device component manufacturers, BDK understand the importance of reliable adhesives in their construction. It is essential that the components work correctly and efficiently whilst being protected and securely fastened within the device.

Discuss your medical device components requirements

Following the Technical and Medical Innovation Trend

BDK are leading the way in medical adhesive conversions and this includes medical diagnostic devices and components. Whether it’s an invasive or non-invasive glucose monitor, heart rate or blood pressure monitor, every device’s internal and external structure requires innovative and efficient bonding solutions. We use our wealth of knowledge and expertise to manufacture components for diagnostic devices such as:

✔ Lateral flow devices

✔ Blood glucose test strips

✔ Diabetes applications

✔ Antibiotic tests

✔ Blood/urine/sweat/food tests

✔ Double sided spacer tapes

✔ Microfluidic layers (channels)

✔ Hydrophilic PET lid

✔ Breathable e-PTFE membranes

✔ PCR seals

Diabetic Glucometer and Test Strip Components

BDK manufactures adhesive components for glucometers. Also known as a glucose meter or a blood glucose monitoring device, they are designed to simply measure blood sugar levels. Used by diabetics, a glucometer is an advanced way to monitor glucose amounts in order to identify where lifestyle changes need to be made or recognise when levels are dangerously high or low.

Diabetic test strips are one of the most vital components of the glucometer device as these are used to take the sample of blood and measure the blood sugar levels within it. They do this by combining the blood sample with a chemical called glucose oxidase, causing it to react and produce gluconic acid. This reaction then creates an electrical current which alters depending on the level of gluconic acid that has been produced; the computer chip converts this current into a numerical reading, finally displaying the glucose level.

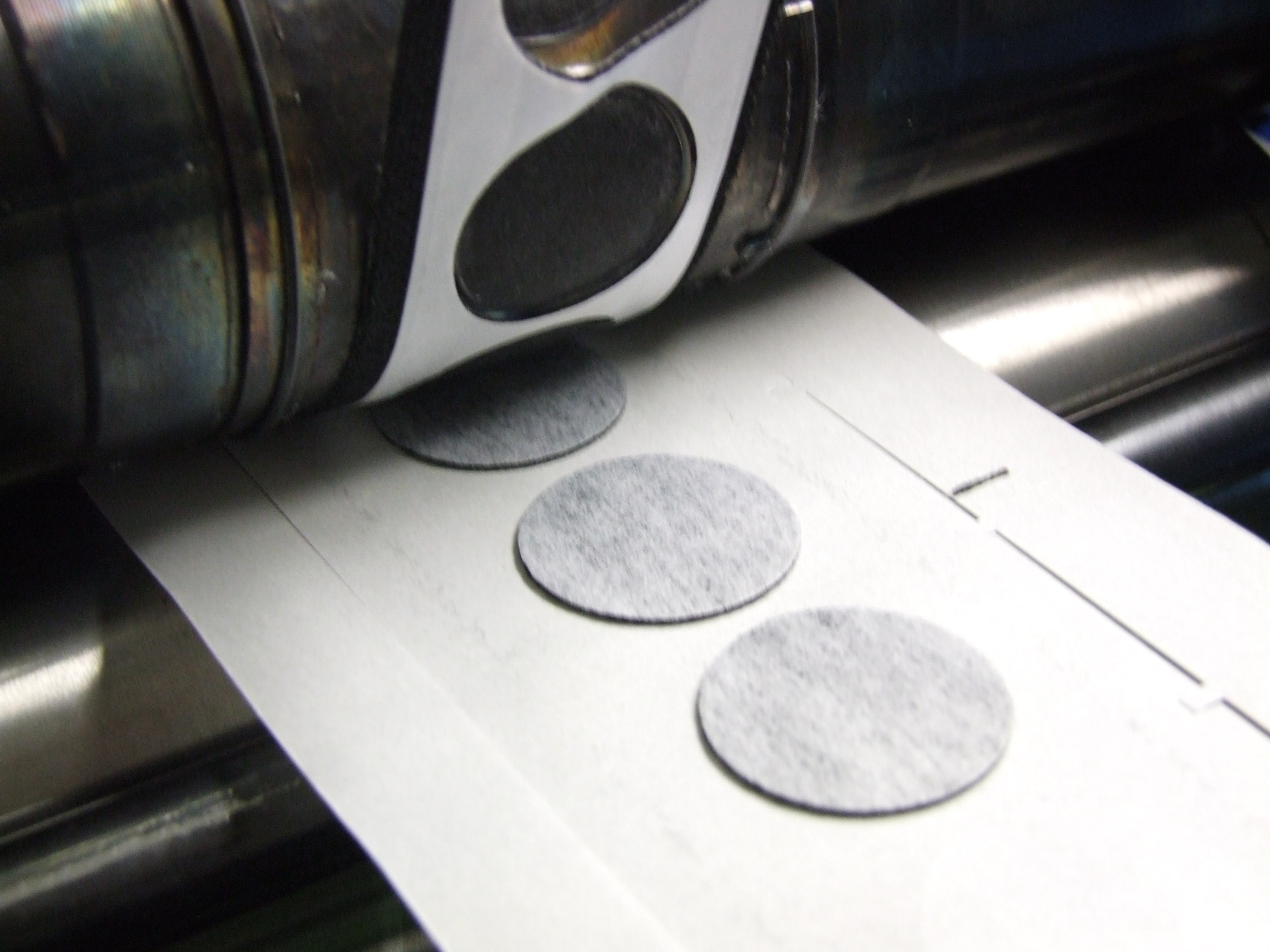

There are a number of diabetic test strip components due to its multi-layered structure. The base layer is where the conductive circuits and enzymes are printed, onto which an accurately cut double sided adhesive is laminated. This inert adhesive stops it reacting with the chemistry and it contains a capillary channel, typically 1mm in width. The blood is then drawn into this capillary which is facilitated by the layer above. The final layer is a top tape which covers and obscures all preceding layers.

Due to the multitude of components within diabetic test strips, the choice of adhesive is vital in the construction; it needs to comply with the different chemicals and materials that are essential for the technology.

Contact us to find out more information and how we can help you.

View all Medical Devices at BDK:

Why use

| 90+ | Members of Staff |

|---|---|

| 1959 | Year established |

| 90+ | Products used in over 90 countries |

| 20m+ | Parts manufactured per year |

| 300+ | Different materials stocked |

| 2007 | ISO13485 since 2007 |