Conformability

Skin-Friendly

Biocompatibility

Protection

BDK Manufacture Advanced Wound Care Dressings

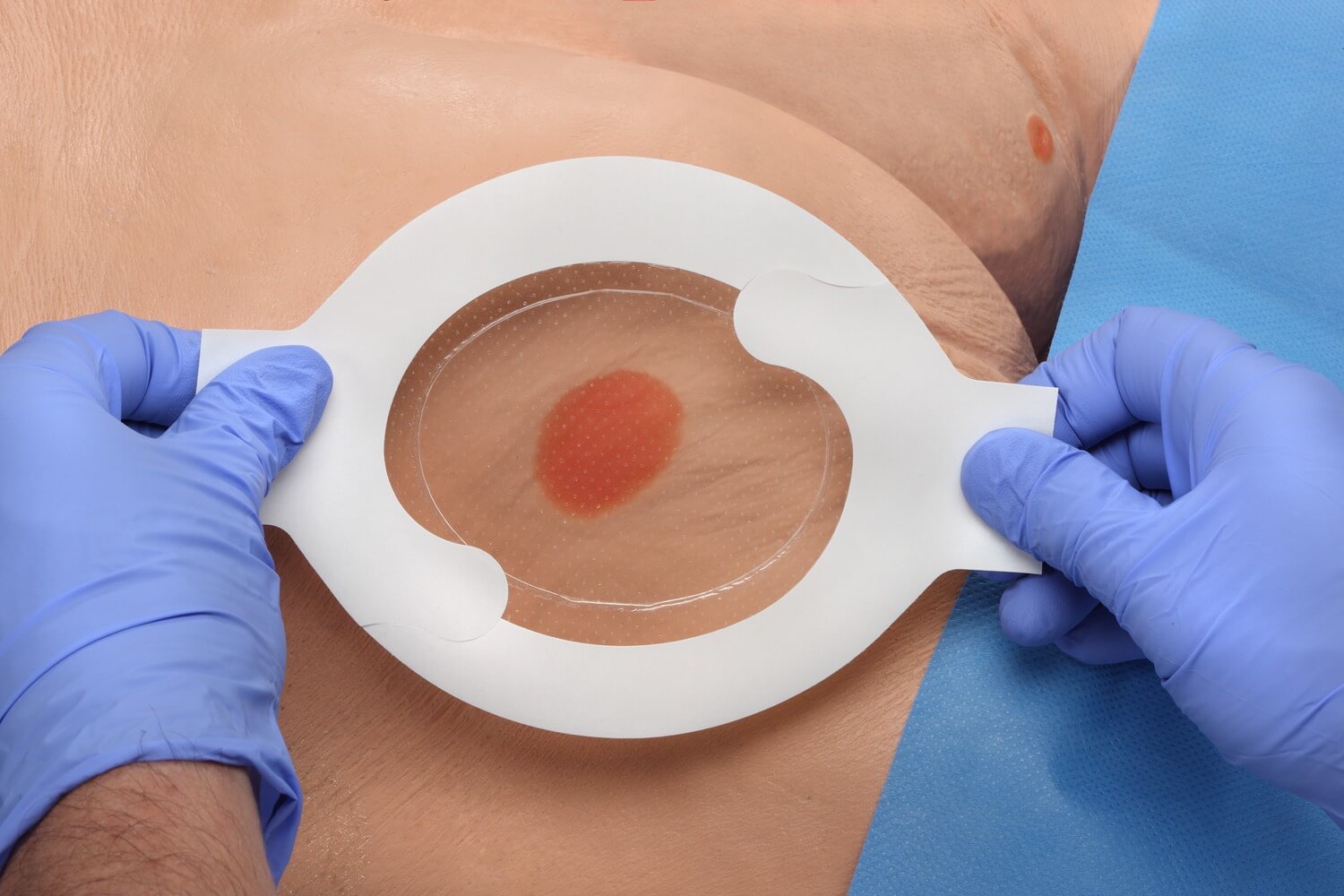

In the healthcare industry, the choice of wound care products is vital. They must make patients feel as comfortable as possible, whilst similarly ensuring that the healing process runs smoothly and efficiently. The ever-changing state of skin and the variety of wounds that can occur are just some of the factors to take into consideration when it comes to advanced wound care.

At BDK we provide products that are compatible with the way skin moves, sweats, breathes, stretches and heals, etc. As a result, we can provide perfect designs, materials and similarly project management. We’re the best choice to develop your desired wound care dressing, whether patients are elderly, young or the wound is chronic.

Our 60 years of experience in conversion to provide advanced wound care products; we are an innovative medical convertor and partner to some of the leading healthcare organisations. With our extended capabilities, we can ensure that your healthcare solutions deliver optimal protection, secure adhesion and easy application.

Discuss your advanced wound care requirements

Applications

From pressure ulcers to infected wounds and burns, we understand the importance of skin-friendly, comfortable components for patients. We have experience creating many types of wound & skin care products, including:

✔ Foam Island dressings

✔ Hydrogel dressings

✔ Hydrocolloid dressings

✔ Alginate dressings

✔ Silver dressings (Ag or PHMB)

✔ Honey dressings

✔ Active ingredients (Aloe Vera, vitamin E etc)

✔ Film dressings – IV, Fixation etc.

✔ Silicone dressings

Bespoke Wound Care Management

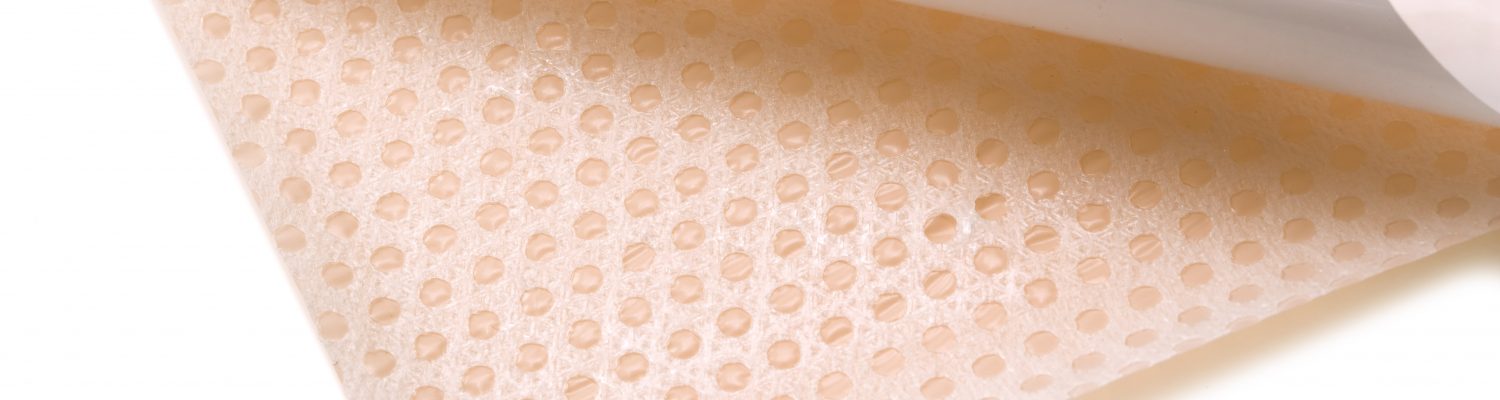

Silicone gel dressings and silicone gel wound contact layers are soft and gentle. Our silicone gel dressings and wound contact layers are soft and flexible, allowing a comfortable healing process over a long period of time. They are gentle and biocompatible with the skin, offering atraumatic removal from the skin and repositioning without compromising adherence.

Perforated silicone gel wound contact layers are becoming increasingly popular. This is because the perforation pattern ensures exudate is drawn away.

At BDK, we have the capabilities to ensure that perforation patterns consist of consistent hole sizes so the silicone gel adhesive can perform with complete efficiency. On top of this, our manufacturing process ensures uniformity and repeatability of perforated silicone gel wound contact layers, so the same high-level performance is achieved with every dressing.

Contact us today to discuss your advanced wound care requirements and we will utilise our knowledge and expertise of the industry to find the perfect solution for you.

View all Medical Devices at BDK:

Why use

| 90+ | Members of Staff |

|---|---|

| 1959 | Year established |

| 90+ | Products used in over 90 countries |

| 20m+ | Parts manufactured per year |

| 300+ | Different materials stocked |

| 2007 | ISO13485 since 2007 |