Thermal Management

Electrically Conductive

Vibration Control

Durable

Electrical Bonding Adhesive Tapes & Components

We are living in a technology-focused world with electronics dominating nearly every aspect of our varying lifestyles. The forefront of revolution, electronic design and manufacturing is quickly evolving and there is high demand from consumers. There is now a great need for electrically conductive adhesive tapes and components, for both size and weight management.

It is vital that every product is reliable and innovative for today, as well as the future.

As the years go by, electronic devices are getting faster and more powerful, all the while more compact; manufacturers not only need to keep up with these advancements, but also make sure they use the most suitable adhesive components.

BDK use combined expertise to find a perfect solution that meets the increasingly demanding operating parameters, in addition to widening design flexibility and improving production efficiency.

Highly Experienced in the Electonics Industry

At BDK, we can help you build better devices with innovative adhesive solutions tailored to your application. We are determined to keep up with the constantly changing and wavering trends of the electronics industry and, with our knowledge and experience, we are committed to tackling any challenge.

By understanding customer demands of lighter, smaller, but durable products, we guarantee that our wide range of adhesives will meet their requirements.

Electrically Conductive Tapes and Adhesives

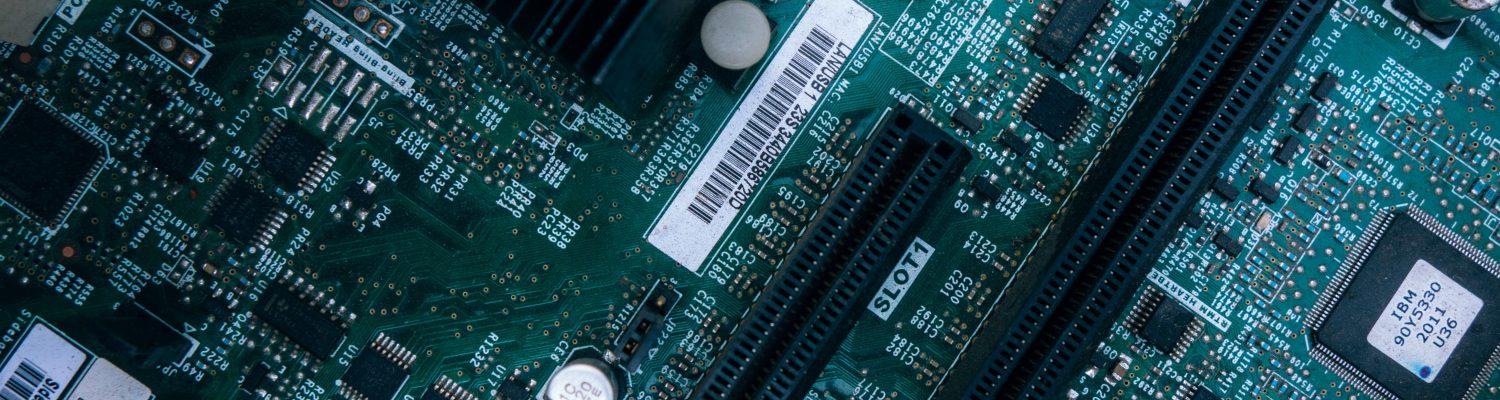

Printed circuit boards (PCB) are present in the majority of electronic products and are used to electrically connect electronic components and mechanically support them. PCBs are constantly reducing in size which is ultimately presenting a challenge to ensure that contacts and components are still able to work reliably. Luckily, flexible electrically conductive adhesives offer an accurate solution for PCB joints, together with protection for sensitive components. By using tapes and adhesive as alternate forms of PCB bonding, they can provide shock and vibration control giving them more durability.

Anisotropic conductive adhesives (ACA) are commonly used for PCBs as the specific conductive particles within these components are able to conduct electricity in one direction. For other applications which require electricity to be conducted in all directions, like surface-mount devices (SMD) or chip contacting, isotropic conductive adhesives (ICA) are better suited. Some of the benefits of using electrically conductive adhesives are that they are both lead and solvent-free, and they are heat resistant which makes them ideal for temperature-sensitive substrates.

We supply a wide range of thermal tape and Kapton tape which are compatible with a wide temperature range and are utilised for high temperature masking on electronic components. By using these thermally conductive adhesives for methods such as wave soldering, hot air levelling (HAL) and powder coating, they will create a high-performing finish without leaving any residue or generating any static charges. We always aim to combine both innovation and collaboration so we can offer materials for electronics that meet bonding requirements and exceed customer expectations.

Whether it’s circuit placement or encapsulation, layer bonding or optically clear bonding, call BDK today to discuss electrically conductive adhesives and how we can help you drive your innovations forward.

Why use

| 90+ | Members of Staff |

|---|---|

| 1959 | Year established |

| 90+ | Products used in over 90 countries |

| 20m+ | Parts manufactured per year |

| 300+ | Different materials stocked |

| 2007 | ISO13485 since 2007 |